Other than yankin’ apart tons of dumpy frames, any of you have a good source for practice lugs? The joint doesnt really matter: Im just practicing my brazing and would rather not shell out the money on new lugs/lug sets.

- There is a dumb questions thread.

- There is a frame building thread.

- Make your own out of scrap tubing.

ceeway

where do people get the idea taking apart frames is even possible? i have done a few repairs and fuck me if it aint 10x as hard as building from scratch

I’m sure I’ve written this before. Find a local steel supply that does 1020 DOM in thinwall, get some pieces where the OD of one fits in the ID of the other. Go at the larger piece with a hole saw to make a miter with a shoreline and all that. Enjoy.

Grant Peterson has spread a lot of bullshit saying that lugged steel is easily repairable (and implying that nothing else is), when here in reality just getting the tube out takes a shitload of skill + some luck, and it’s a hell of a lot easier to cut+grind a TIGged or fillet-brazed joint (even for a skilled lug brazer). Getting a new tube into an old lug is even worse.

Grant Peterson has spread a lot of bullshit saying that lugged steel is easily repairable (and implying that nothing else is), when here in reality just getting the tube out takes a shitload of skill + some luck, and it’s a hell of a lot easier to cut+grind a TIGged or fillet-brazed joint (even for a skilled lug brazer). Getting a new tube into an old lug is even worse.[/quote]

I figured itd be irritating, and possibly not worth the time theyd take to clean up, but theres a lot of fucked up bikes in the scrap metal bin at the co-op I work at, that would otherwise be melted down. Thats the only reason I thought of their lugs as an option, but from what yall say its too much trouble.

I’m sure I’ve written this before. Find a local steel supply that does 1020 DOM in thinwall, get some pieces where the OD of one fits in the ID of the other. Go at the larger piece with a hole saw to make a miter with a shoreline and all that. Enjoy.[/quote]

Thanks! The flow shouldnt be much different than if I were to use cast lugs, assuming that everything is cleaned and prepped properly, correct?

I searched the site, but couldnt find any good matches for “practice lugs”.

If you can find .035 wall, then the flow should work about the same. Anything thicker will be a bit easier to work with than bicycle tubing. That said, it’s a good and cheap way to get a lot of practice under your belt, which is worth a lot.

- cut up old frame

- cut off a short piece of down tube, like 1/2 inch or whatever

- grind out like 1/4" section of it

- compress it slightly so it’s snug and you can

- braze it onto a piece of toptube

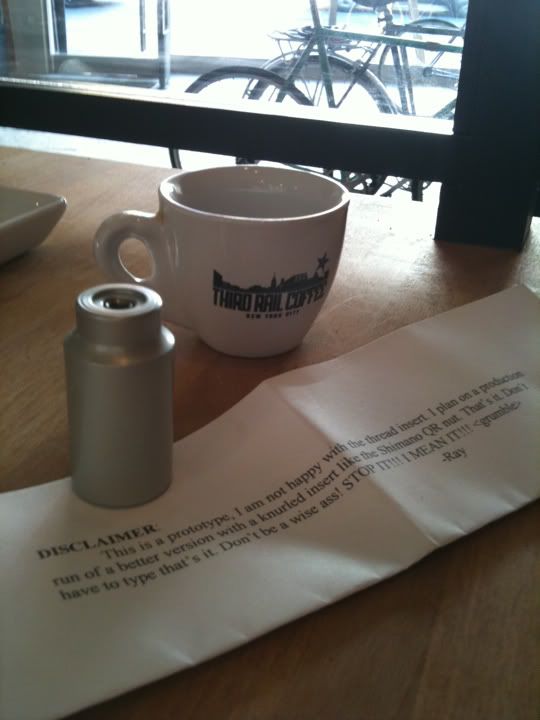

Nice vise…

working on your stufffs…

<3

you too Heath…

Hugs…

something is fucked on that vice, Ray. I got it at a tag sale for 5 bucks, and the bolt holding it to the swivel base is too short or the threads in the vice are stripped. not so good as a bench vice anymore.

good for brazing, but I need to get another one for bench stuff (removing stuck seatposts , etc.)

[quote=Sneaky Viking]1. cut up old frame

2. cut off a short piece of down tube, like 1/2 inch or whatever

3. grind out like 1/4" section of it

4. compress it slightly so it’s snug and you can

5. braze it onto a piece of toptube

Radical! Thank you as well, this is the perfect way to start.

the best, but not worth it unless you’re in the UK.

I’ve got 2 or 3 sets of long shen lugs that are collecting dust. Drop me a PM with you address and I’ll send them to you.

Taking apart a frame is not very cost effective. If the time it takes to cut up the frame, heat the shit out of it to pull apart the lugs, and clean them up to get them ready for brazing is worth less to you than the $10 a lug, well…

[quote=Sneaky Viking]something is fucked on that vice, Ray. I got it at a tag sale for 5 bucks, and the bolt holding it to the swivel base is too short or the threads in the vice are stripped. not so good as a bench vice anymore.

good for brazing, but I need to get another one for bench stuff (removing stuck seatposts , etc.)[/quote]

Have you tried removing it from the swivel base and bolting the vice directly to the bench sans swivel base? I know some people dig a swivel base, but if you put the vice at the corner of your bench then you can easily work on 3 sides of whatever is in the vice.