I really like true temper. They were dickiw at nahbs. HJ doesn’t stock nearly as much stuff as nova. Even though their tubing is better it kinda stinks you still need to do a seperate order somewhere else for all the little crap.

This seat tube is the only TT one in this bike: we’ll be ok.

Wishboner? Lemme see dat.

I lied, the steerer is also TT.

[quote=Eric Estlund]

I lied, the steerer is also TT.[/quote]

That fork is beautiful.

I have hot/ cold valve envy.

Thanks- trying to keep the lug cuts stylish but conservative on this one.

[quote=Eric Estlund]I have hot/ cold valve envy.

[/quote]

you shouldn’t.

they both leak.

I close them with a peening hammer

The hard close. Sweet. You’d leak a little if you were 100 years old, too.

I added a flickr album with some shots of that bike under construction. Luchtreiziger

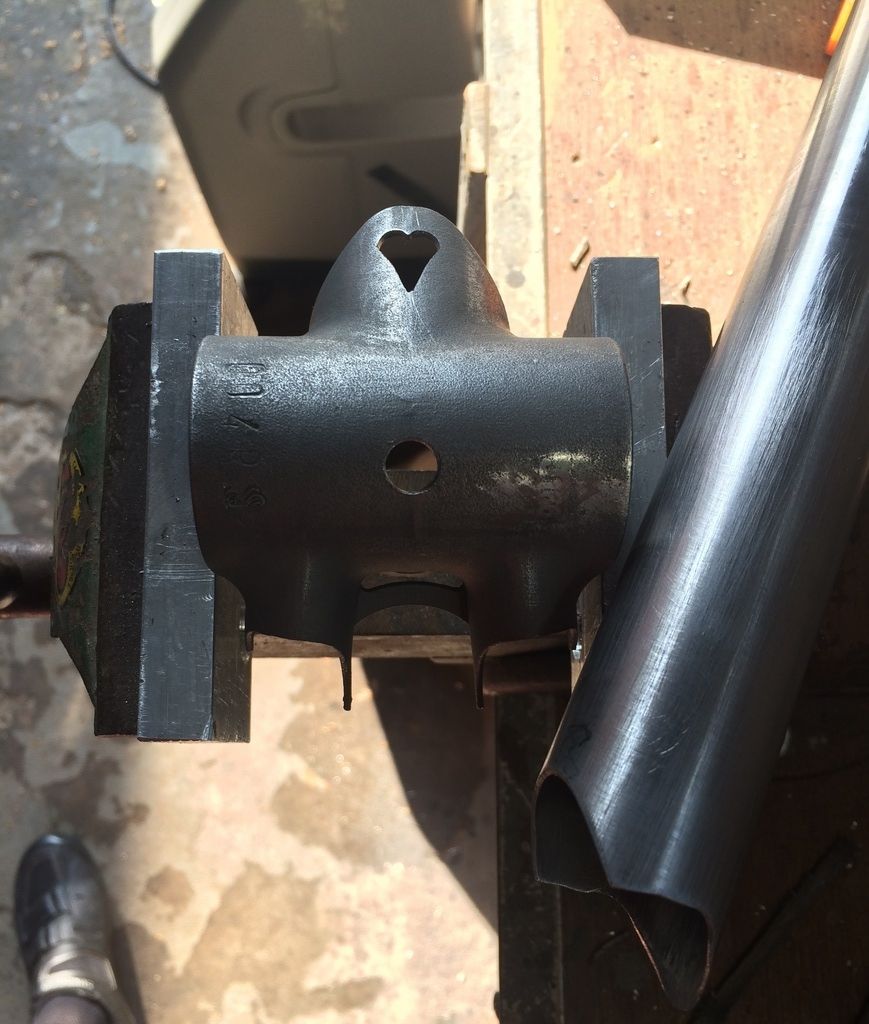

Which is cuter- the little heart or the wittle vise?

eric did your bikes turn german when you moved to pennsylvania or wat

Vice is small but it works.

Gonna get a bigger one, and put it somewhere where I get at it from 3 sides, when I reno the garage.

Is there a trick with those number/letter punches? I seem to be be pretty bad with them.

Ha- that’s Dutch. Hell, it might be German, too- I’m beholden to Google Translate.

A little more from the brasserie-

Are you just running a bead? Try on some wider material. That stuff is all edges and will heat up/ loose heat quickly. A little less edge and a little more thermal mass will help slow things down a bit (on both the heating and cooling). Might be easier to get constant results.

Made this one today:

Bunch of process and finished shots on IG and Flickr.

Yeah I was trying to just run a bead and then I tried doing some “towers”.

I went back in the shop tonight I tried my hand at a joint again. I was surprised to find that those exercises last night really seemed to help. Much easier to build up the fillet to a consistent size. I did find that sometimes I would really get rolling and easily melt the rod into the puddle and move along at a constant speed then things would get stuck and just couldn’t keep the puddle liquid. Smaller tip seemed to help too.

Two pieces of 1 1/4" 0.035" 4130 with a 90deg miter.

I bought a box of 4130 scraps from aircraft spruce and put them all together. I went from total garbage to… ok yeah this joint looks good most the way around.

Yeah that’s pretty much what I’m doing. Got the grab bag deal of 1ft scraps and then I just got like 6ft each of 0.035 in 1", 1 1/8" and 1 1/4".

I also ordered a bunch of the cycle design lfb and flux. Looking forward to using that stuff because the flux I have now is terrible. I mean it works but It’s hard to mix with water and get the right consistency and it just does not soak off like at all.

Are you on oxy-propane Jordan? I am and I’m using a #2 tip. Took me about 15min or maybe more to do the two passes on that joint, too long? I get kinda nervous when things are hot like that for so long…

First off- why two passes?

Second- 15m is a long time. It’s practice, so it’s not big deal, but including preheat I’m only at a joint for a few minutes. Most of which is pre-heating.