Part fillet cross bike for myself. Needs bosses, bridge and seatstay RD stops still. Really happy with the fillets.

One minute of many: real time tipping

Is that part of that MAX frameset you are building?

Yup, all big shapely tubes in that junction.

Framebuilding update

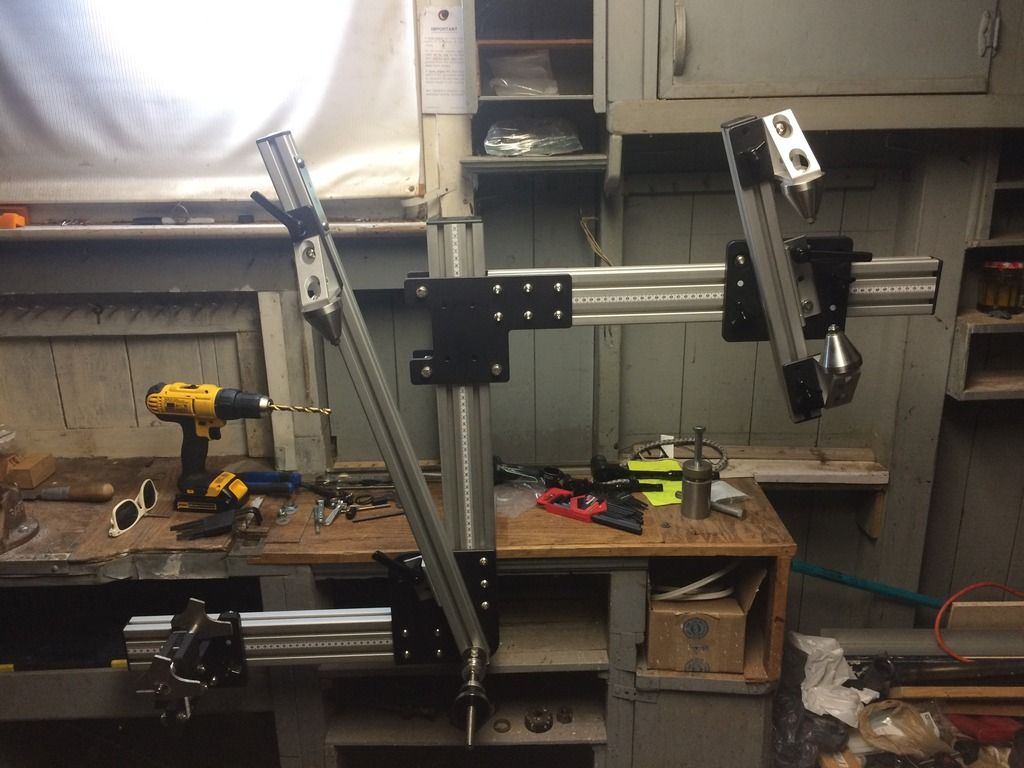

I own this now:

And next project is replacing dropouts and removing stops to make this a dedicated sscx rig for catdrewf

I’m selling my steel derosa so next I might build myself a lugged road fixed or keirin style track bike to ride around town.

I’m also getting started on a wetmore knock off fork jig.

Hell yeah Ross!

You might want to beef up that BB stand off. Looks like the fixture puts stuff where it needs to be!

Random out take from yesterday:

Rossin’

The stand off on the fixture? Yeah its just threaded rod. I could probably get a spacer turned to sit behind the inside puck so it tightens against the extrusion and not just against a nut on the rod.

At first I was a bit concerned with the fixture not being as rigid as other designs. Then I reminded myself that it’s just there to hold things and increased rigidy won’t really matter as long as it holds its tolerances over time. The fact that it came with all the subassemblies assembled and calibrated from these guys is what sold me on it over making my own. I just don’t have time for that kind of thing.

Just ordered the 80/20 bits for my fork fixture, excited to start doing forks.

How do you locate the HT on that? I see the rules, but with different head tubes sitting at different heights on the HT lower cone I’m not sure how they would work. I’m not familiar- if that something someone is selling as a kit?

There’s a reference point on the pivot plate and you use a square to line it up with the bottom of the headtube.

Not really a kit, all the subassemblies were done just the major parts disassembled for shipping.

it looks like a more well built version of the bringhelli jig, less the bb standoff.

That said, setting up the head tube sucks.

There is stuff I’d change, but if the price is right it looks neat. looks way easier to deal with than the first one I made.

The $1599 I paid for one of the first run is about the same as the bringheli, not sure how much the are going to hike the price for the next batch.

Correct me if I’m wrong but with lugs I have been using the full 200mm of headtube and trimming after building. In that case the position of the lower cone doesn’t matter much right? I’m just checking that my DT/HT miter is tight and the angle is correct and then going from there.

yeah sorta how I have been doing it is I just assume the front end isn’t realisting until I get to it miter wise. Then it is much easier to check up on once the tubes are in there

I’m mostly excited to fit up and braze the front triangle in one go, I think that will really reduce the compounded error I was getting when building in subassemblies.

Not sure what you are doing to set it up, but I’ve always used a set amount of stick out below the lower lug (2mm) and have build in my system to locate correctly off this location. I buy HT stock in longer pieces and cut to length, usually leaving 2mm below and 1-4mm above (based on the rough cut) for draw excess as needed and to act as a little heat sink for the flux.

If you have access to a lathe, you may want to make some pucks, or cut steps into the lower cone for your common HT sizes and have hard, repeatable references. It looks like the BB stand off could be beefed up with a piece of lathe cut tube/ pipe/ cored bar pretty easily. More stiffer more betterer.

Gratuitous random photo from the week:

Talk to me about disc mounts. ISO, post, flat mount? What’s easiest at shadetree shop level?